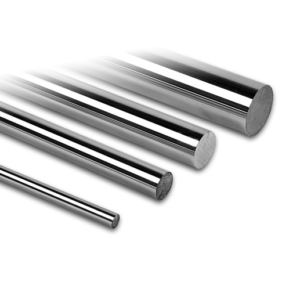

Hardened and Ground Shafts – Built for the Trade

Hardened and ground shafts are the backbone of linear motion. Used in automation, lifting systems, and mechanical assemblies, these shafts are designed for precision, strength, and long service life.

Proper hardening means they won’t wear under constant load. Precision grinding means they slide smooth and true. Get the spec right, and your linear bearings will glide for years. Get it wrong, and it’s misalignment, chatter, and premature wear.

At Godiva Bearings, we stock hardened and ground shafts in standard diameters and lengths, ready for trade-only supply, 24/7.

What Are Hardened and Ground Shafts?

These shafts are solid steel bars that have been heat-treated for surface hardness and then ground to tight tolerances for diameter and finish.

Why it matters:

- Hardening increases wear resistance and load capacity.

- Grinding ensures dimensional accuracy and surface smoothness.

Used with linear bearings, pillow blocks, or custom guides, they provide smooth, consistent travel over time.

What Are They Made Of?

Most hardened and ground shafts are made from:

- Induction-hardened carbon steel (e.g. C45) – A cost-effective option for general use.

- Chromed steel – For corrosion resistance and smoother finishes.

- Stainless steel (e.g. 304 or 440C) – For food-grade, cleanroom or corrosive environments.

Godiva Bearings stocks:

- Standard diameters (6mm to 50mm+)

- Imperial sizes

- Hollow bored options

- Tolerance grades (e.g. h6, h7)

- Cut-to-length options (on request)

Where Are Hardened and Ground Shafts Used?

These shafts are essential wherever guided linear motion is needed:

- Automation and robotics: Guide rails for actuators and positioning systems.

- Material handling: Shafting for conveyors, pick-and-place arms, and guided lifts.

- Machine tools: Precision alignment in CNC routers, milling machines and jigs.

- Printing and packaging: Smooth tracking for tensioning arms and motion stages.

- Medical and lab equipment: Linear travel in sample handlers and optical scanners.

- Food and beverage: Stainless options for washdown zones and conveyors.

- Woodworking machines: For guiding blades, tables, or sanders with minimal friction.

If a machine part needs to move in a straight line with accuracy and low wear, a hardened and ground shaft is probably involved.

What Do Hardened and Ground Shafts Help Prevent?

Correctly specced shafts reduce:

- Misalignment and tracking errors

- Wear and scoring of linear bearings

- Chatter, noise, or vibration during movement

- Failures due to shaft bending or poor surface finish

- Costly downtime from premature component wear

It’s a simple part that makes the whole system work better.

Installation, Use and Maintenance Tips

To get the best from a hardened and ground shaft:

- Always use with matched linear bearings (ball or plain)

- Align shafts precisely to prevent side loading

- Clean regularly to avoid abrasive contamination

- Lubricate bearings per spec – dry shafts can still wear

- Don’t cut or modify hardened surfaces without proper tools

Store shafts flat and supported to avoid warping. Don’t stack loose.

Conclusion: Straight, Strong and Stocked

Hardened and ground shafts aren’t flashy, but they’re foundational. Every clean, accurate, frictionless movement in your customer’s machine starts with one.

Godiva Bearings stocks trade-trusted shafts in popular sizes and grades. Ready for dispatch. Backed by real support.