Slewing Rings Keeping the trade moving

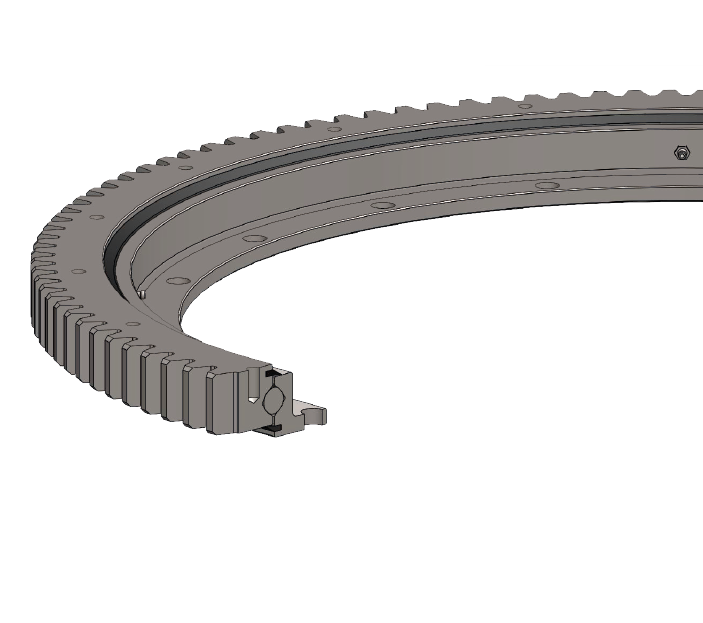

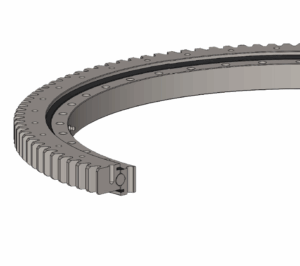

Slewing rings are designed for heavy-duty rotation, combining axial, radial, and moment load handling in one compact unit. From cranes to turntables, they make large-scale movement smooth and controlled.

At Godiva Bearings, we stock a wide range, ready for trade customers — stocked, supported, and ready to ship worldwide.

What are Slewing Rings?

Also called slewing bearings, these are large-diameter rolling-element bearings designed to manage combined loads. Their construction allows rotation under heavy stress while maintaining stability.

Types include:

- Single-row – Compact, economical design

- Double-row – Higher load capacity

- Crossed roller – Precision and rigidity

- Three-row – Maximum load handling for extreme applications

What are Slewing Rings made of?

Built for strength and durability:

- High-grade alloy steel – Heat-treated for load capacity

- Hardened raceways – Reduce wear and extend service life

- Sealed designs – Protect against dirt, dust, and moisture

Lubrication holes and grease fittings are built in for straightforward servicing.

Where are Slewing Rings used?

These bearings are found in demanding industries:

- Cranes and lifting equipment – Smooth, stable rotation

- Excavators and earthmovers – Handles shock and heavy loads

- Wind turbines – Reliable yaw and blade pitch control

- Industrial turntables – Heavy-duty rotation for assembly and welding

- Marine and offshore – Withstands saltwater and harsh conditions

Where strength and precision meet, slewing rings are the solution

Performance and Benefits

Why engineers choose slewing rings:

- Carry axial, radial, and tilting loads in one bearing

- Compact design simplifies assemblies

- Available in multiple configurations for different duty levels

- Long service life with proper lubrication

- Proven reliability in extreme applications

One bearing, multiple roles.

Installation, use and maintenance tips

Best practice:

- Ensure correct mounting surface flatness and rigidity

- Use proper bolt tightening sequence

- Apply recommended lubrication during installation

Maintenance:

- Regularly re-lubricate via grease fittings

- Inspect for wear, corrosion, or noise

- Replace seals as required to protect raceways

Conclusion: Keep it turning

Slewing rings are the cornerstone of heavy-duty rotation, supporting massive loads while ensuring controlled movement. Stocked and supported by Godiva, they’re available for trade customers worldwide.

Access the full range via the Godiva trade portal — always trade-only, always backed by real stock.