Sprockets – Driving force for the Trade

Sprockets transfer torque through chain drives — no belts, no slippage, just direct mechanical power. Whether you’re driving a conveyor or powering a gearbox, a good sprocket means efficiency, alignment, and uptime.

Worn teeth, poor alignment, or the wrong spec? That’s how you get broken chains and noisy runs.

At Godiva Bearings, we stock pilot bore, taper bore, and finished bore versions in simplex, duplex and triplex formats. Trade-only. Always in stock. No web shop tourists.

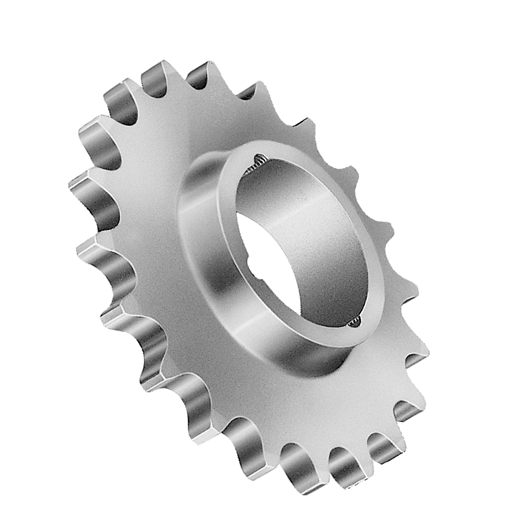

What Are Sprockets?

Basically they are toothed wheels that engage with roller chains to transmit motion and power across shafts.

Unlike belts, they offer:

- No slippage

- Positive drive under load

- High torque transfer with compact design

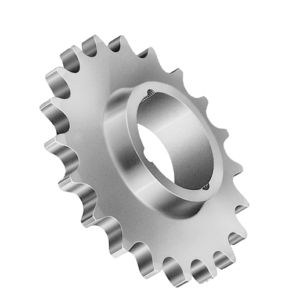

Common formats:

- Simplex – Single row for standard load

- Duplex – Double row for more torque

- Triplex – Triple row for heavy-duty drives

What Are They Made Of?

Godiva Bearings stocks sprockets in tough materials built for the job:

- C45 carbon steel – For standard industrial drives

- Stainless steel – For washdown, food-grade, or corrosive use

- Cast iron (on special order) – For large or slow-speed drives

Most are available as:

- Pilot bore (machined to suit)

- Taper bore (for use with taperlock bushes)

- Finished bore with keyway and grub screws

Where Are Sprockets Used?

You will find them anywhere that chain drives are needed. Key trade applications include:

- Conveyor systems: Driving rollers and moving belts in logistics, warehousing, and packaging

- Agricultural equipment: Chain drives on mowers, balers, harvesters

- Food processing: Stainless sprockets in washdown zones

- Material handling: Bucket elevators, sorters, and indexers

- Industrial drive trains: Connecting gearboxes to driven equipment

- Construction machinery: For track and undercarriage systems

- Bikes and light vehicles: Drive sprockets in hubs and pedals

- Automated machinery: Accurate positioning in pick-and-place arms

They offer positive drive, high torque handling, and simple replacement when worn.

What Do Sprockets Help Prevent?

Fitted correctly they will prevent:

- Chain jumping or skipping under load

- Excessive noise or vibration

- Premature chain wear from poor engagement

- Fatigue in shafts or keys due to misalignment

- Downtime from worn or broken drive components

Always match chain pitch and number of teeth for best performance.

Installation, Use and Maintenance Tips

A few trade best practices:

- Align shafts and sprockets before fitting

- Use taperlock bushes for secure, repeatable fit

- Check for chain wear or elongation

- Lubricate chain per manufacturer guidance

- Inspect regularly for tooth wear, wobble, or surface scoring

Don’t mix old chain with new sprockets — it wears fast.

Conclusion: No Slip. No Nonsense.

Sprockets are the backbone of chain drives. They grip, turn, and transfer power reliably — shift after shift.

Godiva Bearings stocks are tailored to what trade teams ask for: taper, pilot, or finished. Simplex to triplex. Always ready.