V Belts and Timing Belts – Powering the Trade

V belts and timing belts keep power moving without slip, chatter, or stretch. They drive fans, pumps, conveyors, and compressors reliably across thousands of trade and industrial setups.

Where torque needs to move from shaft to shaft, belts do the job with low maintenance and long life.

Godiva Bearings stocks classical, wedge, cogged, and synchronous belts in all sizes and formats. Trade-only. Always supported.

What Are V Belts and Timing Belts?

- V belts transmit power through friction. Their tapered shape grips pulley grooves under tension.

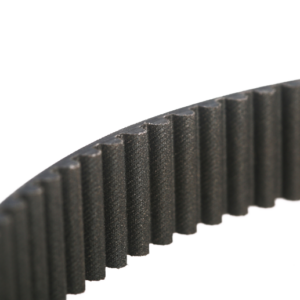

- Timing belts use teeth to deliver precise, slip-free drive. They’re essential where timing or position matters.

We supply:

- Classical and narrow wedge V belts (A, B, C, SPZ, SPA, SPB)

- Raw edge and cogged types for tighter bend radius

- HTD, RPP, and T-series timing belts

- Double-sided belts for reversing or serpentine drives

- Joined and banded belts for high-vibration setups

What Are They Made Of?

Our belts are engineered for performance:

- Rubber or neoprene bodies – Flexible, temperature resistant

- Polyester or aramid tension cords – High-strength, low-stretch

- Nylon-facing (timing belts) – Quiet running and wear-resistant

- PU (polyurethane) timing belts available for clean, high-load zones

Supplied in:

- Standard and metric lengths (pitch or inside)

- Matched sets for multi-belt drives

- Endless or open length (on request)

Where Are v belts and timing belts Used?

Belt drives are everywhere in trade and industry. Common applications include:

- Pumps and compressors: Quiet, smooth torque delivery

- HVAC systems: Fan belts for cooling and airflow

- Packaging machines: Precise movement and repeatability

- Machine tools: Spindles and drive shafts

- Agricultural equipment: Load transfer with flex and resilience

- Food processing: PU timing belts for hygiene-critical drives

- Garage and workshop gear: Air compressors, lifts, and conveyors

If it turns, spins, or drives, there’s a belt on it.

What Do v belts and timing belts Help Prevent?

Properly specced and tensioned belts help avoid:

- Slippage and loss of efficiency

- Excess wear on pulleys and shafts

- Belt cracking or glazing from overheat

- Sudden failure from poor alignment

- Timing loss in synchronised systems

They keep things turning smoothly, shift after shift.

Installation, Use and Maintenance Tips

Trade tips:

- Check pulley alignment before fitting

- Use belt tension tools – guesswork causes failure

- Never force belts over tight pulleys

- Avoid mixing belt types or brands

- Re-tension after bedding-in period

Keep matched sets labelled and stored flat – no coiling.

Conclusion: Keep Power Moving

V belts and timing belts deliver reliable motion, load after load. No slip. No noise. No nonsense.

Godiva Bearings supplies all the belts your job needs — standard or special, always trade-only, always ready.

See our latest video about our in house belt cutting service