A Maintenance Checklist That Keeps Your Food Processing Line Moving

In food production, small problems become big ones fast. A little vibration. A missed lubrication. A seal you meant to check but didn’t. That is how batch loss and audit failures start.

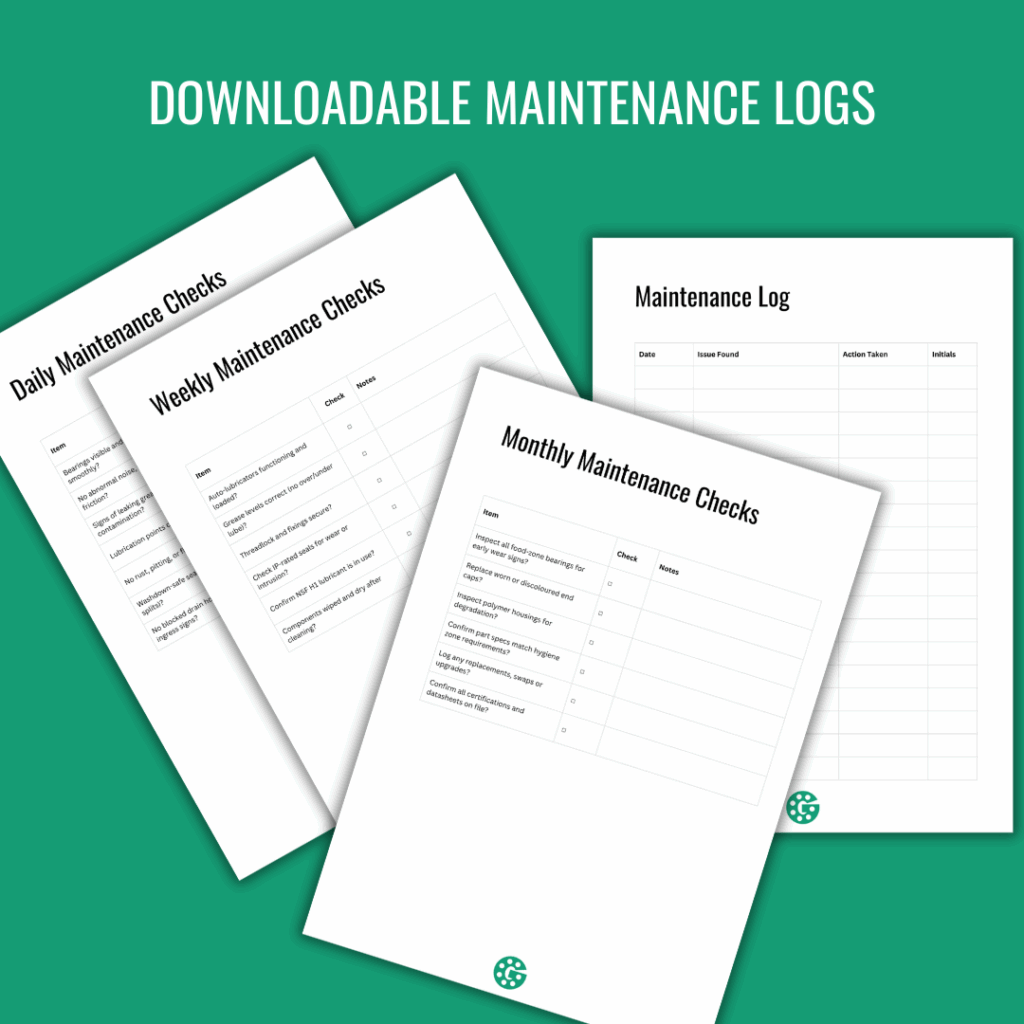

If you are new to food factory maintenance, getting a grip on bearing care is one of the smartest moves you can make. And to help you get it right, we have built a clear, practical tool: our downloadable Maintenance Checklist for Food Processing Lines.

It is designed for real-world use. Quick visual checks that catch problems early, prevent hygiene issues, and reduce bearing-related downtime.

What’s in the Checklist?

The checklist covers daily, weekly, and monthly tasks including:

- Visual bearing checks for rust, wear or grease leaks

- Seal and housing inspections, especially in washdown zones

- Lubrication checks, including auto-lube system status

- Cleaning follow-up checks: dry, clear and safe?

- Certification and spec compliance tracking

- A dedicated log to track issues and fixes

It is laminated-lanyard friendly. And site-engineer approved.

🛠 Download the checklist now and keep it in your tool bag or on the noticeboard.

Why It Matters for New Engineers

Whether you are training up or learning the ropes on the job, knowing how to spot a failing bearing or misaligned mount can save your team hours. More importantly, it can save the product.

If you are not sure what “food-safe” really means or why seals matter so much in a washdown zone, check out these useful reads:

The Value of Keeping a Log

The checklist includes a dedicated maintenance log. It is not just for tracking faults. It is for building knowledge.

Every time you log an issue, you create a trail of learning. You start to spot patterns — repeat failures, high-risk zones, grease types that do or do not hold up.

For apprentices and junior engineers, that log becomes a record of your real-world experience. It helps you build confidence and earn trust. For experienced engineers, it sharpens your diagnostic eye and backs up decisions when things go wrong.

A good logbook shows the job was done right. A great one helps prevent the next failure.

One Last Tip

Every failed bearing has warning signs. This checklist helps you find them before they ruin your shift.

Stick to the schedule. Use the log. Ask questions. And remember: clean, spec’d, and correctly lubricated bearings make all the difference.

📥 Download the checklist and make it part of your daily routine.

TOM HAMLETT

Tom Hamlett is a respected authority in the global bearings marketplace, with over 35 years of experience in industrial bearings, lubricants, and adhesives across a wide range of industries. As Managing Director of Godiva Bearings, Tom has built a trusted business renowned for its commitment to quality, technical expertise, and ethical service. Under his leadership, Godiva Bearings has remained the UK’s only trade-exclusive bearings supplier, proudly serving engineers and distributors worldwide since 1977. Tom’s in-depth knowledge and dedication have cemented his reputation as one of the most knowledgeable figures in the sector.